Ultraviolet disinfection is a proven and highly efficient method for water purification without the use of chemical additives. The benefits of ultraviolet light as a disinfectant and germicide has long been recognized as a great chemical free option in water treatment. In this post, we will explore the use of UV in water treatment.

What is Ultraviolet Light?

Ultraviolet light is actually a low-level form of radiation. Ultraviolet light is defined as radiation (light) having a wavelength shorter than 3900 angstroms the wavelengths of visible light, and longer than 100 angstroms, the wavelengths of x-ray’s. This wavelength puts ultraviolet light at the invisible violet end of the light spectrum. Radiant energy in the ultraviolet region of the spectrum, which has wavelengths shorter than visible light, is lethal to microorganisms. The radiant energy of light is the size of the light’s wavelength, measured in nanometers. Wavelength of light can also be represented by colors like a rainbow. Germicidal disinfection by light falls between 200 and 300 nanometers with the most efficient wavelength at 260 nm. A typical germicidal ultraviolet lamp that’s used residentially has a wavelength of 254 nanometers. The UV light disinfects the water because it penetrates microorganisms, such as E. coli, and damages their DNA so that they are unable to reproduce and are technically dead. This is the preferred method of destroying bacteria because it achieves 99.999% reduction. Sunlight naturally contains UV light and is used as a disinfectant on surface waters and retention ponds in water treatment facilities. In the residential water treatment industry, we use a much more concentrated form of UV light contained in a vessel for disinfection and sterilization.

UV Intensity and Function

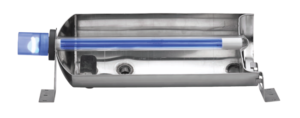

Master Water Conditioning UV units consists of three parts: a power pack supply, UV lamp, and UV stainless steel vessel. A UV unit functions fairly simply. A UV lamp, filled with mercury vapor, is housed in a specially protected quartz sleeve inside a stainless steel chamber. The lamp is connected to a power pack that provides power and measures lamp intensity. Once turned on, the mercury gas in the lamp becomes excited and emits UV light. Water enters the chamber of the vessel, passes around the protective quartz sleeve containing the lamp, is sterilized, and then leaves the chamber for use in a home. The unit’s intensity is the product of the UV lamp’s power, the diameter of the UV cylinder, and the treatment’s flow rate in gallons per second. This is expressed in units called micro watt-seconds per square centimeter. Microwatts is the measurement of the energy emitted from the lamp. The energy availability is also dependent on the UV transmission of the water and varies with the color, metal particles, and turbidity of the water. The more interference the UV light has reaching the microorganism, the less effective it is in disinfecting the water. Seconds is the time the contaminated water is exposed to the UV lamp. Flow rates are converted from gal/sec to a more common measurement of gallons/minute. Square centimeter is the area of the pressure vessel (cylinder). A typical UV unit should produce at least 30,000 MW-sec/cm2 after 12 months of use.

The UV lamps are made of special quartz glass that allows up to 90% transmission of the 254 nm wavelength of light. Standard glass will block almost all of light at this wavelength. The quartz obtains the optimum temperature of 104º (F) needed for 100% UV output for bactericidal radiation. That means the lamp is very hot to the touch. The inside of a UV lamp contains at least one metal coil to conduct the electrical energy from the ballast, an inert gas, typically mercury. When electrical energy enters the lamp through the metal coil, the mercury gas is vaporized and the 254 nanometer wavelength of light is formed. Pieces of metal mercury can be seen in a used UV lamp. This is normal during lamp operation.

High efficiency germicidal lamp emitting 254 nanometers of UV energy for up to 9,000 hours (1 year). The 254 nanometers is the optimum wave length of UV light for destroying bacteria.

UV Units and Applications

• The MWC-E Series - Our standard UV unit. Comes with Stainless Steel Chamber, Power Supply, Germicidal lamp & Quartz and is equipped with an audible alarm to warn of lamp failure.

• The MWC-ES Series - All features of our standard UV unit plus a 1” normally closed solenoid to shut off water supply during a power failure.

• The MWC-EM Series - All features of our ES Series, plus a narrow band UV meter which monitors the 254 nanometer’s wavelength. It features a visual monitor, an audible alarm, a 30 second delay and fail safe circuitry designed to activate the normally closed 1” solenoid valve, which will shut off the water supply during periods of inadequate UV intensity as monitored by the narrow band UV meter.

Performance and Maintenance

The UV system is equipped with a lamp sensor and alarm to insure that the lamp is working. Otherwise, the lamp would have to be physically inspected to see if light is being produced. All units are equipped with a power supply that incorporates an alarm system to indicate proper voltage going to the UV lamp. If the alarm sounds, the UV lamp or power supply has malfunctioned. The power supply provides an electrical connection that operates an optional normally closed solenoid valve to stop water flow when the lamp fails. Most UV lamp manufacturers rate their lamps for 9000 hours or one year of operation. That doesn’t mean the lamp won’t last longer, but an annual replacement is recommended. The quartz tube should always be removed from the cylinder for cleaning when replacing a lamp. A clean quartz provides maximum UV energy transfer from the lamp to the water.

You can learn more about our UV Disinfection systems here.